Table of Contents

ToggleIntroduction

In the rapidly growing skincare and aesthetics industry, brands are constantly seeking innovative ways to offer cutting-edge treatments and personalized tools. Among the most in-demand microneedling devices is the derma stamp—designed for targeted skin rejuvenation, scar treatment, and collagen stimulation. For businesses aiming to bring a unique version of this tool to market, understanding the ODM Derma Stamp Process is essential. This specialized development pathway not only allows for full product customization but also accelerates time-to-market with expert manufacturing support.

ODM, or Original Design Manufacturing, refers to a process in which a product is designed and manufactured by one company and branded and sold by another. In the context of derma stamp production, this means a skincare brand can work with an experienced ODM partner to co-develop a fully branded microneedling device without having to build their own factory or engineering team. This opens the door for startups, dermatology clinics, and established cosmetic brands to launch high-quality, private-labeled derma stamps that meet exacting performance and regulatory standards.

The Rise of Microneedling and Derma Stamps

Microneedling has evolved from a niche clinical treatment to a mainstream skincare solution for improving skin texture, reducing fine lines, and enhancing product absorption. Derma stamps, in particular, offer a precise, vertical application that reduces trauma to the skin compared to traditional rollers. Their compact size, hygiene-friendly design, and adaptability make them a favorite among professionals and at-home users alike.

This increasing demand creates a competitive advantage for brands that can offer a superior, tailor-made tool—enter the ODM Derma Stamp Process. By leveraging the technical and creative capabilities of an ODM manufacturer, brands can focus on marketing, sales, and user experience while relying on experts to handle engineering, safety, and compliance.

Why the ODM Model Matters in Skincare Innovation

The ODM model is especially relevant in today’s skincare market, where product differentiation and speed are key to staying ahead. With the ODM Derma Stamp Process, businesses gain access to a turnkey solution that streamlines product development—from initial concept to final packaging. This process ensures your brand not only meets market needs but also aligns with your identity, values, and clinical performance goals.

Whether you’re a brand looking to expand your product line or a clinic aiming to offer white-label tools, mastering the ODM Derma Stamp Process is a smart strategic move.

What is the ODM Derma Stamp Process?

The ODM Derma Stamp Process refers to the specialized method through which a skincare brand collaborates with a manufacturing partner to design, develop, and produce a custom derma stamp device under its own brand. ODM stands for Original Design Manufacturer, a business model where a supplier is responsible not only for manufacturing the product but also for providing its design and development. This allows brands to launch high-quality, unique microneedling tools without needing in-house product engineering or production facilities.

This process is particularly relevant in the skincare and aesthetic device industry, where product innovation, safety, and performance are non-negotiable. With more consumers seeking results-driven home devices and professional treatments, derma stamps have emerged as a popular alternative to traditional rollers. These devices offer greater control, better hygiene, and more targeted treatment—making them an ideal candidate for customization through ODM partnerships.

Unlike OEM (Original Equipment Manufacturing), where the buyer provides the product design, ODM allows the manufacturer to contribute their own innovation to the development process. OBM (Original Brand Manufacturing), on the other hand, is when the manufacturer not only develops and produces the product but also sells it under their own brand—something not typically aligned with private-label goals. Thus, the ODM Derma Stamp Process offers the sweet spot: the flexibility to tailor your own unique derma stamp while leveraging expert knowledge in microneedling technology.

Key Features of the ODM Derma Stamp Process

The ODM Derma Stamp Process is appealing for its ability to blend creativity and practicality. Here are some of its core features:

- Customization Flexibility: Brands can select the needle type, length, material, handle design, and even integrate advanced features like serum infusion or smart sensors. This allows for a derma stamp that not only meets market needs but also reflects brand aesthetics and values.

- Intellectual Property Protection: ODM partners often help secure IP rights or patents, ensuring your design isn’t replicated by competitors. This exclusivity is especially valuable in a saturated market.

- End-to-End Support: From CAD design to packaging, testing, and compliance, the ODM process is often turnkey. Manufacturers guide clients through every stage—offering faster timelines and higher efficiency.

Evolution of Microneedling Tools

Microneedling began with manual rollers, which used cylindrical barrels covered with tiny needles to stimulate collagen production. While effective, these tools lacked precision and were harder to sterilize. Derma stamps evolved to address these issues, offering vertical application, smaller treatment zones, and single-use formats. With automation and innovation accelerating, modern derma stamps—especially those produced via the ODM process—combine functionality, safety, and beauty in one sleek device.

Key Stages in the ODM Derma Stamp Process

The ODM Derma Stamp Process is a comprehensive development path that transforms an initial idea into a functional, brand-aligned microneedling product. Each stage is designed to streamline innovation while ensuring safety, performance, and market readiness. From early ideation to prototype testing, this process involves close collaboration between the skincare brand and the ODM partner to ensure every detail supports the end-user experience.

Idea Generation and Market Validation

Every successful product begins with a validated idea. During this first phase, the focus is on identifying gaps in the market or unmet consumer needs. This could involve reviewing current derma stamp offerings, analyzing reviews, tracking skincare trends, and studying competitors. ODM partners often support this process by offering insights from prior launches or user data to help define a viable concept.

Equally important is defining the target customer persona. Is the product intended for beginners at home, professionals in clinical settings, or consumers with specific skin concerns like acne scarring or hyperpigmentation? By answering these questions early, the brand and manufacturer can shape a clear product strategy that guides all design and marketing decisions later in the process.

Design and Material Selection

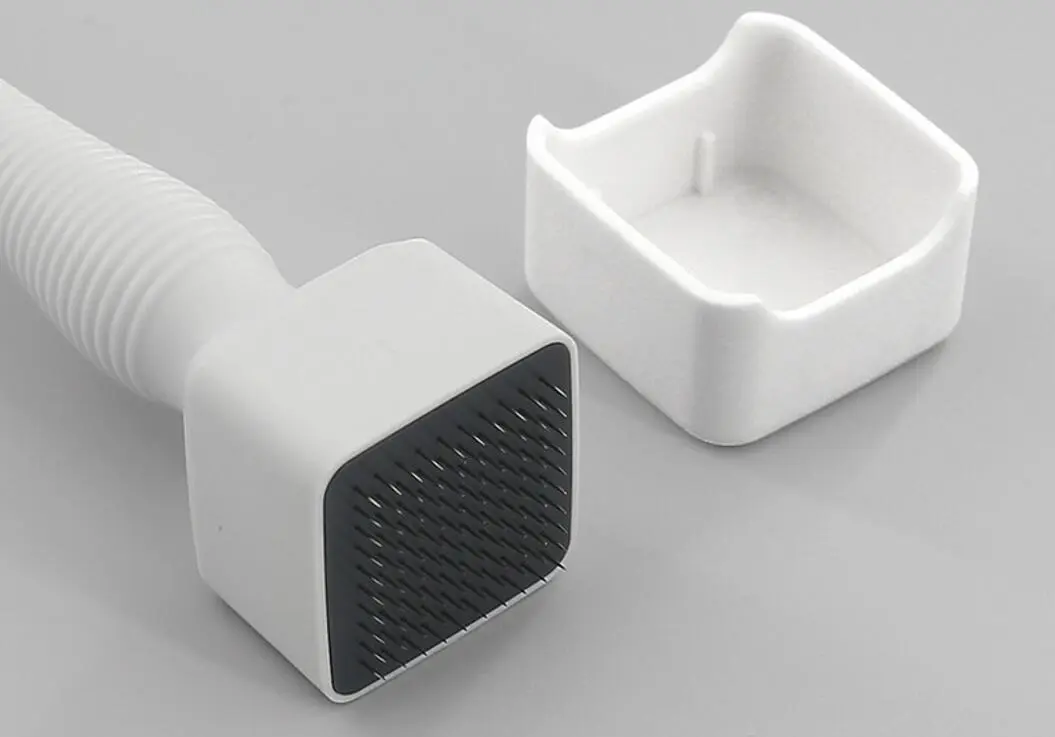

Once the concept is clear, the next step in the ODM Derma Stamp Process is transforming that idea into a detailed product design. This phase begins with sketching and 3D CAD modeling, where ergonomics, visual identity, and technical specs are considered simultaneously. Brands work with engineers to define how the derma stamp will look, feel, and perform.

Material selection is critical here. Skin-safe, medical-grade materials must be chosen for both the needles and the housing. Stainless steel or titanium are often selected for precision and durability, while the stamp handle and body might use ABS plastic, silicone grips, or biodegradable materials for a sustainable angle. These choices affect not only safety and function, but also the brand’s image and values.

Prototyping and ODM Derma Stamp Process Testing

In this phase, ideas become tangible. ODM manufacturers produce prototypes using rapid tooling or 3D printing. These early models are tested for comfort, usability, and performance. Elements like needle sharpness, depth control, and stability are assessed in real-world conditions.

The ODM Derma Stamp Process also involves rigorous internal quality checks and possibly third-party trials. User feedback is collected and applied to refine the product before moving to mass production. These iterations ensure that the final product performs consistently and meets both regulatory and user expectations.

Customization Options in the ODM Derma Stamp Process

Customization is at the heart of the ODM Derma Stamp Process, allowing skincare brands to design a microneedling tool that is both functionally effective and visually aligned with their identity. Unlike generic products, ODM customization provides full control over product appearance, usability, and features—ensuring that every detail supports your brand’s market strategy.

Branding and packaging are among the most immediate and visible customization options. Through the ODM Derma Stamp Process, you can choose your own color palette, logo placement, surface texture, and even design bespoke packaging that reflects the essence of your brand. Whether you want a minimalist aesthetic for a luxury line or eco-friendly materials for a clean beauty brand, every aspect can be tailored. This helps your derma stamp stand out both online and on physical retail shelves.

In terms of functionality, adjustable needle depths are one of the most valuable features ODM manufacturers offer. This allows your product to cater to various skin concerns and sensitivity levels, offering flexibility for users to target specific areas more effectively. Some designs feature built-in dials or interchangeable heads, giving the customer control over their treatment while ensuring safety and comfort.

The ODM Derma Stamp Process also supports more advanced customization through technology integrations. For example, smart features like LED therapy, usage timers, or Bluetooth tracking can be embedded into the device. These innovations increase product value and appeal, especially to tech-savvy skincare consumers who are looking for personalized and data-driven beauty routines.

ODM Derma Stamp Process and Brand Positioning

The level of customization possible through the ODM Derma Stamp Process directly impacts your brand’s positioning in the market. In a space where many products look and function similarly, having a derma stamp with unique design, specialized features, and branded packaging creates a strong competitive edge. Whether your goal is to attract clinical professionals, eco-conscious consumers, or trend-following beauty enthusiasts, customization helps communicate your message and values clearly. Ultimately, a well-customized product elevates your brand from just another skincare tool provider to a standout leader in innovation and identity.

Technology & Manufacturing in the ODM Derma Stamp Process

The ODM Derma Stamp Process relies heavily on advanced technology and precise manufacturing techniques to produce high-quality microneedling devices. Automation, CNC (Computer Numerical Control) machining, and cleanroom production play crucial roles in ensuring that each derma stamp meets the highest standards for safety and performance. These technologies allow for consistent precision in needle alignment, smooth ergonomic designs, and seamless assembly. Automated systems streamline production, reducing human error and increasing efficiency, which ultimately leads to faster delivery times for brands and more affordable pricing.

Automation, CNC Machining, Cleanroom Production

Automation in the ODM Derma Stamp Process helps ensure that every part of the device is manufactured with consistency and precision. CNC machining, a key aspect of this process, enables the creation of complex components like needle heads and handles with incredible accuracy. This level of precision is vital in microneedling, as even slight deviations can compromise the device’s performance. Cleanroom production is equally important, as it minimizes contamination risks during assembly and packaging, guaranteeing that the final product is sterile and ready for use in sensitive skincare treatments.

Certification, Compliance & Documentation

Certification and compliance are essential elements of the ODM Derma Stamp Process, ensuring that the product meets safety standards and is legally marketable in various regions. Obtaining certifications such as ISO (International Organization for Standardization), FDA (U.S. Food and Drug Administration), and CE (Conformité Européene) is crucial for ensuring product safety and regulatory approval. Each certification requires detailed documentation, including testing results, product specifications, and compliance with manufacturing standards.

To prepare for these certifications, brands must work closely with their ODM partners, ensuring that all necessary documentation is in place. This includes compliance with industry standards on material safety, manufacturing processes, and sterilization procedures. Adhering to these certifications not only builds consumer trust but also ensures the product is suitable for both home and professional use in global markets.

From Factory to Market

The ODM Derma Stamp Process doesn’t end with production; it extends into the critical stages of delivery, packaging, and post-manufacturing support. Once the product has been designed, tested, and finalized, the next step is getting it from the factory to the market. This process involves managing order quantities, ensuring timely delivery, and arranging effective packaging to protect and showcase the product. Supply chain efficiency is essential for brands looking to launch products quickly and reliably. By collaborating with a trusted ODM partner, skincare brands can streamline these processes and make sure their derma stamps reach customers in optimal condition.

Order Quantities, Lead Time, and Packaging

During the ODM Derma Stamp Process, order quantities are an important factor in both pricing and scheduling. ODM manufacturers typically offer tiered pricing based on order volume, with larger quantities allowing for cost savings per unit. Lead time, or the amount of time required for manufacturing and shipping, can vary depending on the complexity of the design, material sourcing, and other factors. Therefore, early planning is key to ensuring that brands meet product launch deadlines and avoid delays in reaching their target market.

Packaging is another critical aspect, as it not only ensures the safe transport of products but also contributes to branding. Custom-designed packaging that matches the aesthetic of the derma stamp can make a significant impact on the consumer’s first impression. Whether opting for eco-friendly materials or luxury packaging, the right choice reflects the brand’s values and enhances the overall customer experience.

ODM Partner Collaboration

Throughout the ODM Derma Stamp Process, collaboration between the brand and the ODM partner is essential to ensure a smooth transition from manufacturing to distribution. Effective communication tools—such as project management software, regular video calls, and milestone planning—help keep the process on track. By setting clear milestones, both parties can ensure that each stage of development meets the expected timeline.

Another vital part of collaboration is maintaining proper product documentation. This includes specifications for materials, manufacturing processes, and certifications. Having detailed records of these elements helps facilitate a smooth manufacturing process, allows for easy troubleshooting, and ensures compliance with regulatory requirements. Proper documentation also provides the brand with the information needed for marketing, retail, and customer support.

Case Study: Launching a Successful Derma Stamp Brand

Launching a derma stamp brand can be an exciting but challenging endeavor. Let’s look at a fictional case study of GlowSkin, a skincare brand focused on sensitive skin solutions, and how they successfully used the ODM Derma Stamp Process to create and launch their product.

Pain Points

GlowSkin initially faced several pain points in the competitive skincare market. The founders knew there was a growing demand for home-use microneedling tools but struggled to differentiate themselves from established brands. They also lacked in-house expertise to design and manufacture a custom derma stamp, which would meet both their aesthetic and functional needs. Their primary concerns were ensuring the device was safe, effective, and comfortable for sensitive skin, as well as meeting industry regulatory standards.

Solutions

By partnering with an experienced ODM manufacturer, GlowSkin gained access to advanced design and manufacturing capabilities. The ODM partner helped them create a derma stamp with adjustable needle lengths, a soft silicone grip, and hypoallergenic titanium needles. They also ensured the device was compliant with both international and local regulations for skincare devices. The product went through extensive testing, with feedback from real users guiding the design adjustments, particularly for ease of use and needle safety.

Successful Outcome

Thanks to their strategic partnership, GlowSkin successfully launched a product that stood out in a crowded market. Their derma stamp was praised for its gentle performance on sensitive skin and its sleek, eco-friendly packaging. Within six months, the brand saw a 30% increase in sales and expanded its customer base, ultimately positioning GlowSkin as a trusted name in skincare tools.

This case highlights how the ODM Derma Stamp Process can turn challenges into opportunities for growth and market success.

Common Challenges in the ODM Derma Stamp Journey

The ODM Derma Stamp Process is a multi-step journey that involves collaboration between skincare brands and manufacturers. While it offers significant benefits, such as access to customized products and manufacturing expertise, there are also several challenges that can arise throughout the journey. Brands must be aware of these potential obstacles to ensure a smooth process and a successful final product.

Design Misalignment

One of the most common challenges in the ODM Derma Stamp Process is design misalignment. This occurs when the final product doesn’t align with the original vision due to communication gaps between the brand and the manufacturer. Often, design elements that seem simple in concept—such as the ergonomic fit of the handle or the needle length—can be difficult to execute precisely, especially if both parties aren’t on the same page. Misunderstandings about aesthetic preferences, functionality, or usability can lead to prototypes that need multiple revisions, which can delay the production timeline and increase costs.

To prevent this, it’s crucial to have clear and frequent communication with the manufacturer from the start. Regular updates and feedback loops can help identify issues early and ensure that the design evolves in line with the brand’s vision and consumer needs. Using detailed 3D models and prototypes can also help catch potential issues before mass production begins.

Communication with Manufacturers

Effective communication is essential for a smooth ODM process. Poor communication can lead to delays, misunderstandings, and even issues with product quality. Skincare brands must work closely with their ODM partner to set clear expectations about product features, design specifications, timelines, and quality standards. Language barriers, cultural differences, or time zone challenges can sometimes complicate communication, particularly if the manufacturer is based overseas.

Establishing a clear project management system with milestones, deadlines, and detailed documentation can help keep the process on track. Regular virtual meetings, progress reports, and in-person visits (when possible) can facilitate smoother collaboration and ensure that everyone is aligned at each stage of the journey.

Product-Market Fit Testing

Once the product is designed and manufactured, testing it for product-market fit is essential to determine whether it resonates with consumers. Many brands make the mistake of skipping or rushing this phase, assuming that a well-designed derma stamp will automatically be successful. However, product-market fit testing is critical for ensuring that the product meets consumer needs, addresses pain points, and delivers the expected benefits.

Testing involves gathering feedback from real users—whether through surveys, focus groups, or beta testing—to identify any design flaws, usability issues, or performance concerns. It’s important to listen to this feedback and be willing to make adjustments to the product, even if it means additional time and costs. Conducting thorough market research, analyzing consumer behavior, and iterating on the design will ultimately ensure the product is well-suited for its intended audience.

By addressing these challenges early in the ODM Derma Stamp Process, skincare brands can successfully navigate the journey from concept to product launch. Clear communication, careful design, and thorough market testing will result in a high-quality product that meets consumer expectations and stands out in a competitive marketplace.

Conclusion

The ODM Derma Stamp Process offers significant advantages for skincare brands looking to create a high-quality, customized product that meets both consumer expectations and industry standards. This process ensures that brands can develop a unique derma stamp tailored to their specific needs, whether it’s for targeting sensitive skin, offering adjustable needle depths, or ensuring ease of use in home treatments. By partnering with experienced ODM manufacturers, brands gain access to design expertise, advanced technology, and high-quality production capabilities that might be otherwise difficult to achieve independently.

Recap of Key Stages

To summarize, the ODM Derma Stamp Process typically begins with idea generation and market validation. This is followed by design and material selection, where brands and manufacturers collaborate to define the product’s aesthetic, functionality, and safety features. After the concept is finalized, prototyping and testing come into play. Prototypes allow for real-world validation, helping to identify any issues before mass production. Once the design is refined, production begins, with the final product undergoing strict quality control checks to ensure compliance with regulatory standards.

Customization is one of the most significant benefits of the ODM Derma Stamp Process, as it allows brands to differentiate themselves in a crowded market. From branding and packaging to functional features, such as adjustable needle depths and ergonomic designs, the possibilities for creating a unique product are virtually limitless. With the support of a reliable ODM partner, brands can also ensure that their product adheres to all relevant certifications and safety standards.

Call to Action (CTA)

If you’re a skincare brand looking to enter the microneedling space or enhance your product lineup, now is the time to explore the ODM Derma Stamp Process. With the right partner, you can bring your vision to life, from concept to market. Reach out today to inquire about our ODM services and learn how we can help you create a customized, high-performance derma stamp that meets your brand’s goals and exceeds customer expectations. Let’s create something extraordinary together!

FAQs Regarding ODM Derma Stamp Process

1. What is the ODM Derma Stamp Process?

The ODM Derma Stamp Process refers to the complete development journey of creating a customized microneedling device through an Original Design Manufacturer (ODM). This process involves collaboration between a skincare brand and an ODM partner to design, test, and manufacture a derma stamp that meets the brand’s specifications and the market’s needs. It includes stages such as idea generation, design and material selection, prototyping, and final production.

2. How long does the ODM Derma Stamp Process take?

The timeline for the ODM Derma Stamp Process can vary depending on factors such as product complexity, design changes, and manufacturing capacity. On average, the process may take anywhere from 3 to 6 months from initial concept to final product delivery. Prototyping and testing phases often extend the timeline as any design adjustments are made.

3. What are the benefits of using an ODM partner for derma stamp production?

Partnering with an ODM for the Derma Stamp Process allows brands to leverage manufacturing expertise, advanced technology, and design customization. It provides access to high-quality production capabilities, reduces the need for in-house resources, and enables faster time-to-market. Additionally, ODM partners often have experience with certifications, compliance, and regulatory approvals, ensuring a smoother process for brands.

4. Can I customize the design of my derma stamp through ODM?

Yes, customization is a significant advantage of the ODM Derma Stamp Process. Brands can work with ODM partners to customize elements such as the handle design, needle length, materials, packaging, and branding. The goal is to create a unique product that aligns with the brand’s identity and meets the specific needs of its target audience.

5. What materials are typically used in the ODM Derma Stamp Process?

In the ODM Derma Stamp Process, materials like medical-grade stainless steel, titanium, and eco-friendly plastics are commonly used. Stainless steel or titanium is selected for the microneedles due to their durability and precision. The handle is often made from materials like ABS plastic, silicone, or biodegradable options, ensuring safety, comfort, and sustainability.

6. How do I ensure my derma stamp is safe for use?

Safety is a top priority in the ODM Derma Stamp Process. Manufacturers must adhere to stringent quality control measures and compliance with relevant certifications such as ISO, FDA, and CE. Before production, a detailed risk assessment and testing phase are conducted to ensure the device’s design, needles, and materials meet safety standards. Post-production, rigorous sterilization and packaging processes further ensure safety for consumers.

7. What types of testing are involved in the ODM Derma Stamp Process?

The ODM Derma Stamp Process includes several rounds of testing, such as functionality tests to ensure the needles align correctly and provide the desired effect. Performance testing ensures that the device performs consistently across different skin types. Additionally, user testing gathers feedback on comfort, ease of use, and safety. These tests help identify any issues before moving to mass production.

8. How can I differentiate my derma stamp from competitors using ODM?

Differentiating your derma stamp can be achieved through various customization options available in the ODM Derma Stamp Process. This includes tailoring the design, material selection, unique features like adjustable needle depth or ergonomic handles, and custom packaging. Additionally, integrating advanced technology such as LED therapy or serum infusion systems can set your product apart from competitors in the market.

9. Are certifications and regulatory compliance important in the ODM Derma Stamp Process?

Yes, certifications and regulatory compliance are essential in the ODM Derma Stamp Process. To ensure safety and market acceptance, manufacturers must meet regulatory standards such as ISO, FDA, and CE certifications. These certifications ensure that the product complies with quality standards, safety protocols, and industry regulations in different regions.

10. What happens after my derma stamp is produced?

After production, the derma stamp undergoes thorough quality checks, packaging, and sterilization. The product is then ready for shipping and distribution to retailers or directly to consumers. Many ODM partners assist in this phase by handling logistics and ensuring that the product reaches the market on time. Once launched, brands typically continue working with their ODM partner for any after-sales support, including addressing consumer feedback or product enhancements.

References

- Dermstore, “The Ultimate Guide to Microneedling”, https://www.dermstore.com/blog/microneedling-guide/

- Healthline, “What Is Microneedling and How Does It Work?”, https://www.healthline.com/health/beauty-skin-care/microneedling

- WebMD, “Microneedling: What to Expect and How It Works”, https://www.webmd.com/skin-problems-and-treatments/guide/microneedling

- Medical News Today, “Microneedling: Benefits, Risks, and How It Works”, https://www.medicalnewstoday.com/articles/microneedling-benefits

- Verywell Health, “Microneedling for Acne Scars: A Complete Guide”, https://www.verywellhealth.com/microneedling-for-acne-scars-5185785

- Mayo Clinic, “Microneedling for Skin Rejuvenation”, https://www.mayoclinic.org/microneedling-for-skin-rejuvenation

- National Institutes of Health (NIH), “Clinical Use of Microneedling in Dermatology”, https://pubmed.ncbi.nlm.nih.gov/clinical-microneedling-dermatology/

- The Derm Review, “What Is Microneedling and How It Helps Skin”, https://thedermreview.com/microneedling/

- Medical Spa MD, “The Truth About Microneedling”, https://www.medicalspamd.com/truth-about-microneedling/

- Skin Health Spa, “The Benefits of Microneedling”, https://www.skinhealthspa.com/benefits-of-microneedling/

- Health.com, “How Microneedling Works and What It Does”, https://www.health.com/microneedling-works-what-it-does-7183411

- Aesthetician Connection, “The Science Behind Microneedling Devices”, https://aestheticianconnection.com/science-of-microneedling-devices/

- Allure, “What Is Microneedling and Does It Actually Work?”, https://www.allure.com/story/what-is-microneedling

- Dermacare, “How to Choose the Right Microneedling Device”, https://www.dermacare.com/choose-right-microneedling-device/

- Skin Inc., “Innovative Microneedling Devices: What’s New?”, https://www.skininc.com/innovative-microneedling-devices-whats-new/

- Beauty Magazine, “Everything You Need to Know About Microneedling”, https://www.beautymagazine.com/microneedling-guide/