Table of Contents

ToggleIntroduction

Exploring the Manufacturing Process of Custom Derma Rollers

In this thorough write-up, we will take you on a journey behind the scenes of our modern production center, supplying a unique peek into the detailed process associated with creating custom derma rollers for our valued OEM and ODM clients. Thoroughly selecting the finest materials and executing strict quality assurance actions tailors each manufacturing step for top-quality derma rollers. By diving into the precise craftsmanship and dedication that underpin our derma roller manufacturing procedure, we aim to display the exceptional commitment to excellence that drives our initiatives in meeting the one-of-a-kind needs of skincare brands worldwide. Join us as we introduce the internal operations of our facility and the precise steps required to ensure the production of derma rollers tailored to the diverse requirements of our well-regarded clients.

Definition and Purpose of Derma Rollers

Microneedle tools known as derma rollers, equipped with small needles, create micro-injuries on the skin’s surface. These gadgets aim to promote collagen production, improve skin texture, and reduce the appearance of scars, wrinkles, and hyperpigmentation.

The idea behind derma rollers is based on the body’s all-natural healing process: by creating regulated damage to the skin, it causes the skin’s repair mechanisms to malfunction, leading to rejuvenation and regeneration. Derma rollers are available in numerous needle lengths, usually ranging from 0.25 mm to 1.5 mm or even more.

Short needles boost absorption; longer ones penetrate deeper for collagen induction therapy (CIT) and exfoliation. The adaptability of derma rollers enables a wide variety of skincare concerns to be attended to efficiently with consistent usage over time.

Importance of Custom Derma Rollers in Skincare Industry

Derma rollers customization plays a vital role in fulfilling the diverse needs and choices of skincare professionals and consumers alike. By offering customization alternatives such as needle size, density, layout, shade variations, and branding opportunities, producers can satisfy the detailed requirements of various skincare brand names or experts.

This degree of customization improves brand identification, establishes products apart in an affordable market, and permits for customized solutions to address specific skin problems. In a sector where customization and innovation are vital drivers of success, custom derma rollers provide a system for creative thinking and differentiation.

Skincare specialists frequently look for distinct tools that align with their treatment methods or branding techniques. Customizing derma rollers makes it possible for producers to team up carefully with customers to establish bespoke remedies that meet their exact requirements while maintaining high criteria of quality and performance.

The demand for custom derma rollers continues to grow as consumers become more critical of their skin care options. With an emphasis on personalized techniques to appeal to routines and treatments customized to specific skin types or problems, individualized derma roller alternatives provide a customized touch that reverberates with today’s beauty-savvy clientele.

Customization has actually come to be progressively crucial in markets like skin care, where personalization is crucial. Customized tools like custom-made dermal rollers allow brand names flexibility in meeting special conference requirements. The capability to personalize offers a chance for producers to engage very closely with customers. There is high demand for personalized charm items as customer choices continue to develop. Brand names can differentiate themselves by providing tailored remedies that stand out in the market.

Material Selection: The Foundation of Quality

The manufacturing process begins with the careful selection of materials that form the foundation of our custom derma rollers. We prioritize top quality and integrity, sourcing just the finest medical-grade stainless steel or titanium needles for ideal performance and durability. Our materials undergo strenuous testing to guarantee they meet rigorous market criteria, ensuring the safety, security, and performance of our derma rollers.

High-Quality Stainless Steel or Titanium for Needles

When it comes to producing custom derma rollers, the choice of product for the needles is crucial. Top-quality stainless steel or titanium are the recommended choices due to their resilience, resistance to rust, and ability to maintain sharpness with time.

Stainless steel is known for its toughness and affordability, making it a popular choice for derma roller needles. On the other hand, titanium provides advantages such as being hypoallergenic and lightweight, making it suitable for sensitive skin types.

Durable Plastic or Metal for Handle

In addition to choosing the best product for the needles, just as crucial is picking a long-lasting material for the handle of custom derma rollers. Handles are frequently made from plastic or metal, each offering special advantages.

Plastic materials are lightweight and economical, making them a sensible selection for mass manufacturing. Steel takes care of supply toughness and a premium feeling, typically preferred by premium skincare brands wanting to improve their product aesthetic appeals.

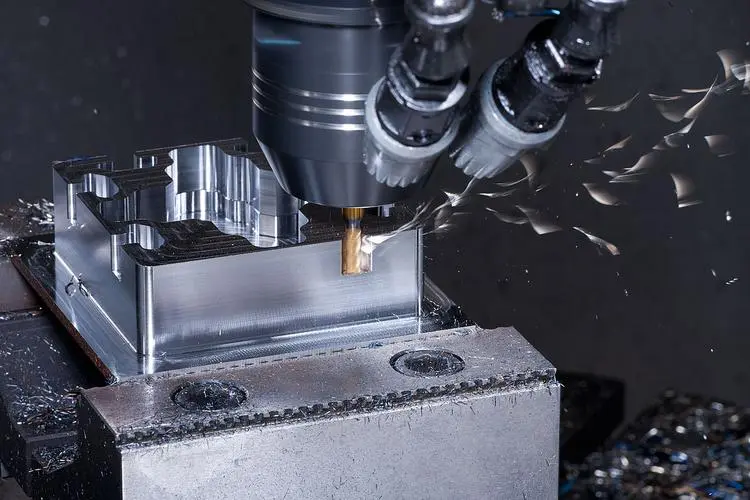

Precision Engineering: Crafting Custom Designs

Our experienced engineers craft custom derma roller styles to align with specifications provided by our OEM and ODM clients. Leveraging modern innovation and accuracy machinery, we thoroughly engineer each derma roller to obtain the desired needle size, thickness, and configuration. This meticulous attention to detail ensures that our derma rollers deliver optimum results across a range of skincare applications. Our custom derma rollers address fine lines, and enhance overall skin appearance, meeting diverse customer demands. By integrating innovative design with unrivaled craftsmanship, we make every effort to boost the standards of excellence in the skin care market, empowering our clients to achieve their skincare goals with self-confidence and efficacy.

Design Considerations for Customization

Needle Length and Density Based on Client Needs

Custom derma rollers use versatility in needle size and density to satisfy specific customer needs. The length of needles figures out the depth of penetration right into the skin, with much shorter needles suitable for surface peeling and longer needles targeting deeper layers for collagen excitement.

Also, needle thickness plays a role in the insurance coverage area and the strength of therapy. Tailoring these elements based on customer choices makes sure tailored skincare solutions provide optimal outcomes.

Handle Design, Color, and Branding Options

Beyond functionality, custom derma rollers enable imaginative layout elements that improve brand identity and consumer charm. Design can vary from sleek minimalistic forms to ergonomic grips tailored for customer comfort during therapies. Shade modification offers unlimited possibilities to straighten with brand-name aesthetic appeals or stick out on retail racks.

Furthermore, branding alternatives such as logo placement or embossing create a sense of exclusivity and professionalism, and trust in the skin care market landscape. With thorough interest in material options and thoughtful consideration of layout aspects in customization procedures, manufacturers can elevate the manufacturing of custom derma rollers to fulfill varied customer demands while maintaining product quality requirements.

Needle Manufacturing: Crafting Precision and Security

Derma rollers are delicately developed skincare tools that count greatly on the accuracy of the cutting and shaping of their needles. The production process starts with choosing top quality stainless-steel or titanium for the needles. These materials are chosen for their stamina, sturdiness, and resistance to corrosion, making sure a long life expectancy for the derma roller.

Each needle is meticulously cut into the preferred length and form, making use of sophisticated machinery run by proficient technicians. As soon as the needles are shaped, they undergo an important sterilization procedure to assure safety and security for customers.

Sterilization is a non-negotiable step in derma roller manufacturing to avoid infections or skin irritations. We rigorously sanitize needles using techniques like autoclaving or gamma irradiation to ensure they’re free from harmful microorganisms.

Handle Assembly: Molding Precision and Security

The handle of a customized derma roller plays a vital role in its functionality and comfort throughout usage. Injection molding is utilized to create handles that are not just ergonomic but also long-lasting enough to withstand repeated usage.

Controlled conditions infuse premium plastic or steel products into molds to achieve specific forms and dimensions for the handles. Once the deals have been formed, the next step entails firmly affixing the sterilized needles to them.

We ensure thorough attention to detail to properly straighten and securely fasten each needle to the handle. We employ adhesives or mechanical fastening methods based on layout needs, applying quality assurance throughout the assembly process.

Manufacturing Process: From Concept to Reality

With the styles wrapped up, the production process kicks into high gear as our group of expert service technicians brings each customized derma roller to life. This intricate process includes a series of accurate steps meticulously performed to make certain the highest quality standards are satisfied.

First of all, the selected products, such as medical-grade stainless steel or titanium, undergo thorough examination to confirm their quality and viability for the planned usage. Once authorized, the products are carefully planned for the manufacturing process.

Next, the manufacturing of the derma roller begins with the marking and shaping of the needles. Our modern equipment and proficient service technicians meticulously shape each needle to the specific specs outlined in the style.

Adhering to the creation of the needles, the roller parts are constructed with precision. This includes straightening the needles with the roller base and safely fastening them to ensure security and sturdiness. Each part is meticulously evaluated throughout the setting up process to guarantee uniformity and harmony across all products.

We rigorously apply quality assurance measures throughout manufacturing to identify and address potential problems or issues promptly. This consists of extensive evaluations at various phases of production to confirm dimensional precision, needle intensity, and overall item stability.

By sticking to rigorous quality requirements and making use of advanced production methods, we make certain that every custom-made derma roller that leaves our center meets the highest possible requirements of high quality, integrity, and performance.

Customization Process: Personalizing Beauty Innovation

Personalization distinguishes typical derma rollers from bespoke ones tailored to satisfy private preferences and branding needs. Laser engraving innovation etches detailed logos or designs onto handles, adding personalization and exclusivity for clients. The accuracy of laser engraving guarantees clear and long lasting imprints that enhance brand recognition in an open market. Beyond aesthetic appeals, modification extends to packaging alternatives designed according to customer specs.

Product packaging works as more than simply a protective covering; it communicates brand name identification and worth via its products, colors, forms, and branding components. From sophisticated boxes adorned with foil-stamped logos to green pouches made from sustainable materials, packaging selections mirror a dedication to top-quality workmanship in every aspect of custom-made derma roller manufacturing.

Customized Needle Options: Enhancing Skincare Precision

When it comes to personalized derma roller production, the option of needles plays an essential role in meeting varied skin care requirements. Nano needles, typically ranging from 0.25 mm to 0.5 mm in length, are perfect for gentle peeling and enhancing item absorption without creating pain. These ultra-fine needles produce micro-channels on the skin’s surface, promoting collagen production and boosting overall skin appearance.

On the other end of the spectrum, mini needles supply deeper infiltration into the skin, ranging from 0.75 mm to 2.5 mm in length. These needles target skin concerns like fine lines and acne scars, enhancing natural rejuvenation processes deeply.

The customization of needle options allows skincare professionals and elegance brands to tailor derma rollers according to individual preferences and treatment goals. By providing a variety of needle sizes and thicknesses, custom derma rollers can attend to different skin problems properly while supplying an individualized skin care experience for users.

Handle Materials: Sustainable Solutions for Eco-Conscious Beauty

In response to expanding ecological concerns, customized derma roller makers have actually started including biodegradable materials into handle styles. Biodegradable alternatives, such as plant-based plastics or compostable materials, use eco-conscious brand names as a possibility to minimize their carbon impact and promote sustainability in the beauty market.

Besides lasting products, take care of styles and concentrate on performance and customer experience. Anti-slip layers on manages offer users a far better grasp throughout therapies, guaranteeing accurate application and decreasing the threat of unexpected slides or pain during use.

Eco-friendly handle materials meet customer demand for sustainability and reflect responsible production practices in the skincare industry. By providing biodegradable options and ergonomic layouts, personalized derma roller suppliers can accommodate ecologically conscious consumers looking for cutting-edge yet green skincare services.

Custom Derma Rollers Quality Control Measures

Inspection under Microscopes to Ensure Needle Sharpness

In the meticulous production procedure of custom derma rollers, one of the vital quality control procedures is the evaluation of needles under high-powered microscopes. Each needle is looked at for its sharpness, making sure that it fulfills the called for standards for reliable skin penetration.

We immediately identify and correct any flaws or dullness in the needles to ensure optimal performance and safety. This level of detail in evaluation guarantees that only the finest quality derma rollers get to the hands of customers.

Drop Tests to Check Durability and Needle Stability

One more lesser-known high quality control action in personalized derma roller production is carrying out decline tests to assess resilience and needle stability. During this examination, assembled derma rollers go through controlled decreases from defined heights onto various surface areas.

The influence replicates unintentional drops or messing up that might take place during shipping or everyday usage. Manufacturers ensure product durability and effectiveness over time by observing roller resilience to environmental effects without compromising needle stability.

Custom Derma Rollers Regulatory Compliance

Adherence to FDA Guidelines on Needle Length and Material Safety

Conformity with FDA guidelines is a critical element of producing custom derma rollers, especially worrying needle size and product security. The FDA regulates medical gadgets like derma rollers to guarantee they satisfy rigorous standards for efficacy and individual safety.

Suppliers need to abide by certain needle length restrictions to prevent prospective skin damage or adverse responses. In addition, make use of accepted products such as medical-grade stainless steel or titanium needles. It ensures that the derma rollers are risk-free for use on the skin without risk of contamination or allergies.

Certification Processes for Medical-Grade Derma Rollers

Acquiring certification for medical-grade derma rollers involves extensive analysis processes by governing bodies such as the FDA or CE. These qualifications validate that custom derma rollers satisfy established criteria for quality, security, and efficiency in skincare applications.

Makers must provide comprehensive documents regarding their manufacturing processes, materials used, quality control measures implemented, and adherence to regulatory demands. Accreditation not only validates the credibility of a producer but additionally imparts self-confidence in customers regarding the efficiency and security of medical-grade derma roller products they select for skincare therapies.

Collaboration and Communication: Partnering for Success

Throughout the production procedure, communication and cooperation are crucial to success. We closely collaborate with OEM and ODM customers, providing tailored guidance and support throughout the manufacturing journey. By fostering collaboration, we empower customers to realize their skincare visions with custom derma rollers that exceed expectations.

Innovation and Continuous Improvement: Driving Excellence

As pioneers in the derma roller market, we dedicate ourselves to innovation and continuous improvement. We invest in R&D to remain at the forefront of technical improvements. We also find brand-new ways to boost the performance and efficiency of our derma rollers. By welcoming technology, we ensure that our customers have access to advanced skincare services that deliver phenomenal results.

Round Up

The Art of Crafting Beauty Microneedling Tools

The production procedure for custom derma rollers is really an art that incorporates precision design with visual style. We carefully select materials, assemble precisely, and personalize modifications to enhance skincare routines and total skin health. The attention paid to the manufacturing procedure ensures that each custom derma roller is of the highest quality.

Elevating Skin Care Experiences

Custom derma rollers play an essential role in boosting skincare experiences for individuals seeking reliable options for various skin problems. Manufacturers empower clients with customization options to tailor derma rollers according to specific preferences and requirements. This level of customization boosts the efficiency and fulfillment stemmed from using these ingenious elegance tools.

Pioneering Innovation in Beauty Industry

As technology advances, custom derma roller production drives innovation in the beauty industry, evolving alongside consumer needs. Suppliers remain at the forefront of trends by incorporating niche subtopics like customized needle options and sustainable handle materials. The dedication to research, study, development, and conformity with regulatory standards underscores the sector’s commitment to advancing skincare techniques.

Empowering Confidence Through Self-Care

Ultimately, the journey from raw materials to finished product symbolizes a commitment to self-care and empowerment, surpassing mere manufacturing. Custom derma rollers empower individuals to control skincare, boost confidence, and embrace alternative beauty approaches.

Investing in high-quality custom beauty devices like derma rollers nurtures not only skincare but also enhances self-esteem, radiating outward. Custom derma roller production showcases the harmonious blend of science, creativity, and customer empowerment in the beauty industry.

Each meticulously crafted roller offers individuals the opportunity to embark on a journey toward healthier skin and enhanced well-being. As we envision the future of skincare advancement, let’s celebrate the transformative potential within these small yet powerful tools. It is a reminder that self-care is not simply a regular activity but a representation of internal stamina and appeal.

Reference:

- Leonna Dsouza, Vivek M. Ghate, Shaila Lewis, Derma rollers in therapy: the transition from cosmetics to transdermal drug delivery, December 2020Biomedical Microdevices 22:77, DOI:10.1007/s10544-020-00530-3

- From Medium, The Best Derma Roller Manufacturer I Ever Met, Dec 26, 2023

- By Lana Burgess, How do dermarollers work?, January 30, 2018

- WIMPOLE CLINIC, Derma Roller for Hair Growth: Expert Review 2024, Medically reviewed by Dr. Michael May (FRCS) — Updated on March 12, 2024